Embellishments

Given the rise in popularity for Embellishments in the apparel industry, we at Apparel Technologies offer the latest solutions to our client base. From embroidery to bonding technology, our production facilities and skilled operators are able to provide you with export quality products at the least cost.

Apparel Technologies take pride in working on the most innovative embellishment techniques, while assisting our clients introduce the new techniques to their buyers. Our plants are capable of offering the following embellishment services.

Embroidery

Our embroidery production plant includes state-of-the-art embroidery machines; Apparel Technologies assures its customers that their 100 strong skilled workforce is capable of handling a variety of embroidery designs. The plant includes state-of-the-art embroidery machines, advanced laser engraving machines and an advanced punching designing division. AppTech assures its customers that their 100 strong skilled workforce along with world class machinery are capable of handling a variety of embroidery techniques while maintaining strict deadlines.

Production according to your need

Our production facility is capable of handling mass production while sticking to strict deadlines, with the plant even running 24/7 to complete production if need be. Quality checks are performed at each stage to ensure that the final product is in line with the requirement of the customer.

Embroidery services offered

- Basic Embroidery

- 3D

- Appliqué

- Bead attaching

- Chenille

- Sequin embroidery

- Sublimation printing on sequins attaching

- Flippy sequins attaching

- Wobbly Sequins attaching

Printing

The future of printed fabrics, we at AppTech uses the latest in digital fabric printing technology, capable of printing on a wide range of fabrics at a fraction of the cost. With the ability to print virtually any design on different materials, you have the opportunity to print large quantities in a short amount of time and making minute changes virtually instantly. Our ink jet printers are sustainable to the environment having very little wastage and ensure that the print quality is sublime. A print cutter machine is also available for poly-cotton textiles as well as sublimation printing.

One of the newest innovations in the apparel industry, sublimation printing allows for crisp and clear designs to be printed without any hassle. App Tech production facility is capable of doing both roller sublimation printing as well as panel form sublimation according to customer demand.

- Roller form Printing

- Panel form Printing

- Sublimation on Sequin

Bonding

Apparel Technologies provide a wide range of bonding techniques using the best technology has to offer and tailor made to suit your requirement. The production facility is capable of handling mass production of various different techniques with a team of highly skilled operators and technicians. All of our production is done with the highest class of materials and machines, which includes the world renowned Italian bonding brand, Framis. Our solutions are tailor made for each customer, providing the exact material required as per the standards required while taking into account the production cost that is available.

Bonding techniques available

- Bonding air holes

- Appliqué bonding

- Sticker bonding

- Garment seam bonding

- Pocket bonding

- Fabric high build bonding

- Zipper bonding with garage

- Sticker bonding (PU transfer)

- Leather bonding

- Foil transfer

Embossing/Debossing

Over the years App Tech has expanded its facilities to cater into latest fashion trends such as embossing and debossing fabrics. Our production plant is capable of achieving a finish of the highest quality while being able to do mass production within a short period of time. Our experts ensures that the latest techniques are available to our clientele.

- Embossing & Debossing

- Embossing Mold Development

Laser services

Our production facilities also include state of the art CNC cutters with which we are able to provide an array of skilled services in laser cutting, which includes: Kiss cutting, engraving: either onto metal, wood or fabric, Fabric cutting, Print guide cutting (printed badges).

The production facility also includes advanced laser engraving machines and an state-of-the-art punching designing division. We are also equipped to provide laser washing service with the highest quality finish.

- Kiss cutting

- Engraving: either onto metal, wood or fabric

- Fabric cutting

- Print guide cutting (printed badges)

- Sticker laser cutting and bonding

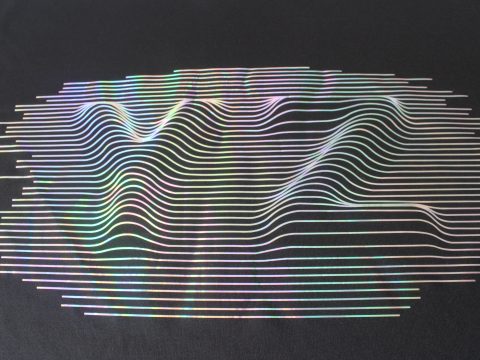

Sequin production

The Bobbin undertakes the manufacturing of sequins based on our customer requirements. Our products come in a wide range of sizes, shapes, and colours to choose from. We also provide customized colour pallets based on the designs of the customer. Time is of the essence when it comes to fashion and we pride ourselves on having a short lead time combined with maintaining in-house stocks. Quality assurance is a significant part of our production process.

Most buyers require a certification to ensure safety and reliability in their garments. Our sequins materials are OEKOTEX certified, the sequin cutting machines are of the highest quality imported from Korea and post production quality checks are performed to ensure that the sequins we produce adhere to the standards required.

Sequin range

- Soft Touch Sequins

- Sublimation Proof

- 3D Effect Sequins

- Dual Colored Sequins

- DTM Sequins As per Client Requirement